What is meant by In Service Welding?

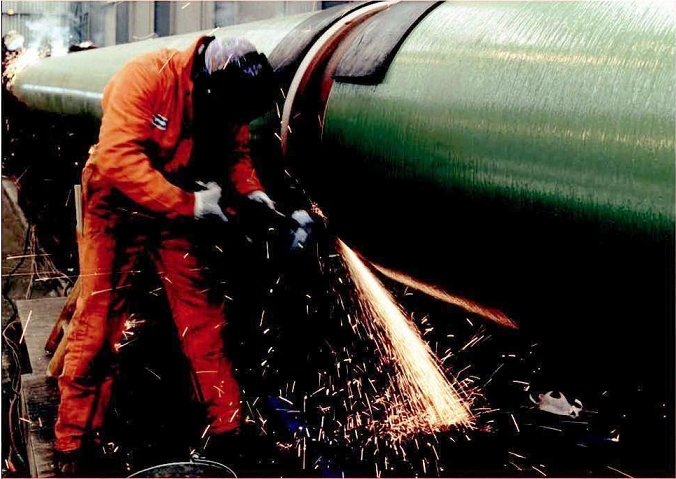

In-Service Welding is a specialized welding on a piping system that is flowing and/or under pressure.

The following considerations are given in an In-service welding process:

- Risk of welding arc causing breach in the pipe wall allowing the contents to escape (burn-through).

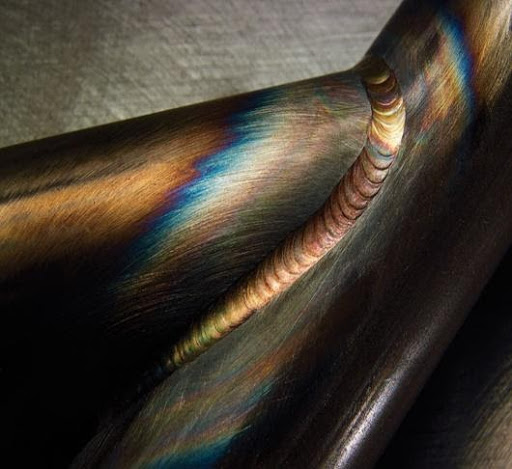

- Integrity of Carbon steel piping system following welding, since weld made in in-service pipeline cool at an accelerated rate as the result of the ability of the flowing contacts to remove heat from the pipe wall. The accelerated cooling causes in-service welds to have hard heat-affected zones (HAZ) and a subsequent susceptibility to Hydrogen Cracking.

- Maximum inside surface temperature during welding